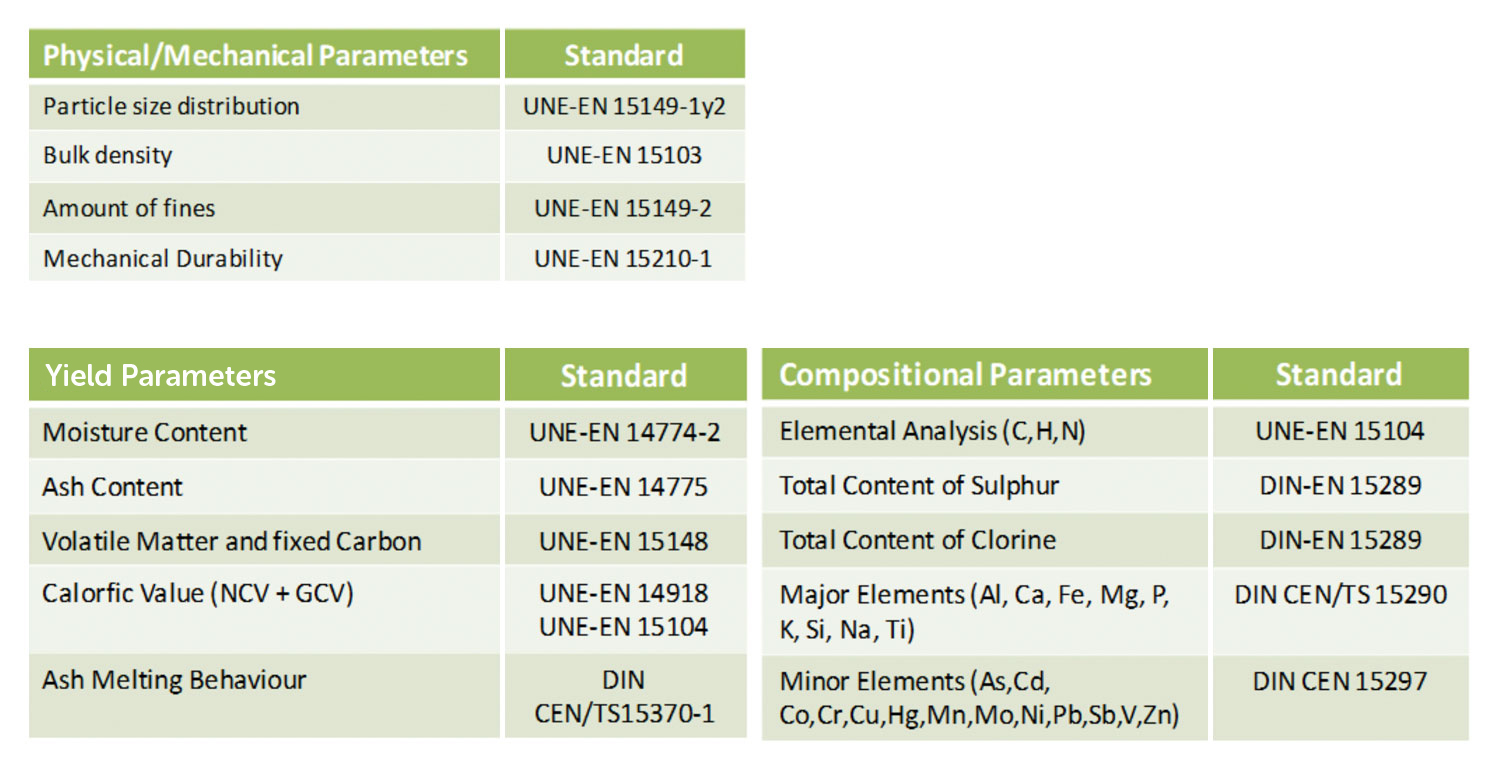

SOLID BIOFUELS LABORATORY

Raw Material and Pellets Characterization

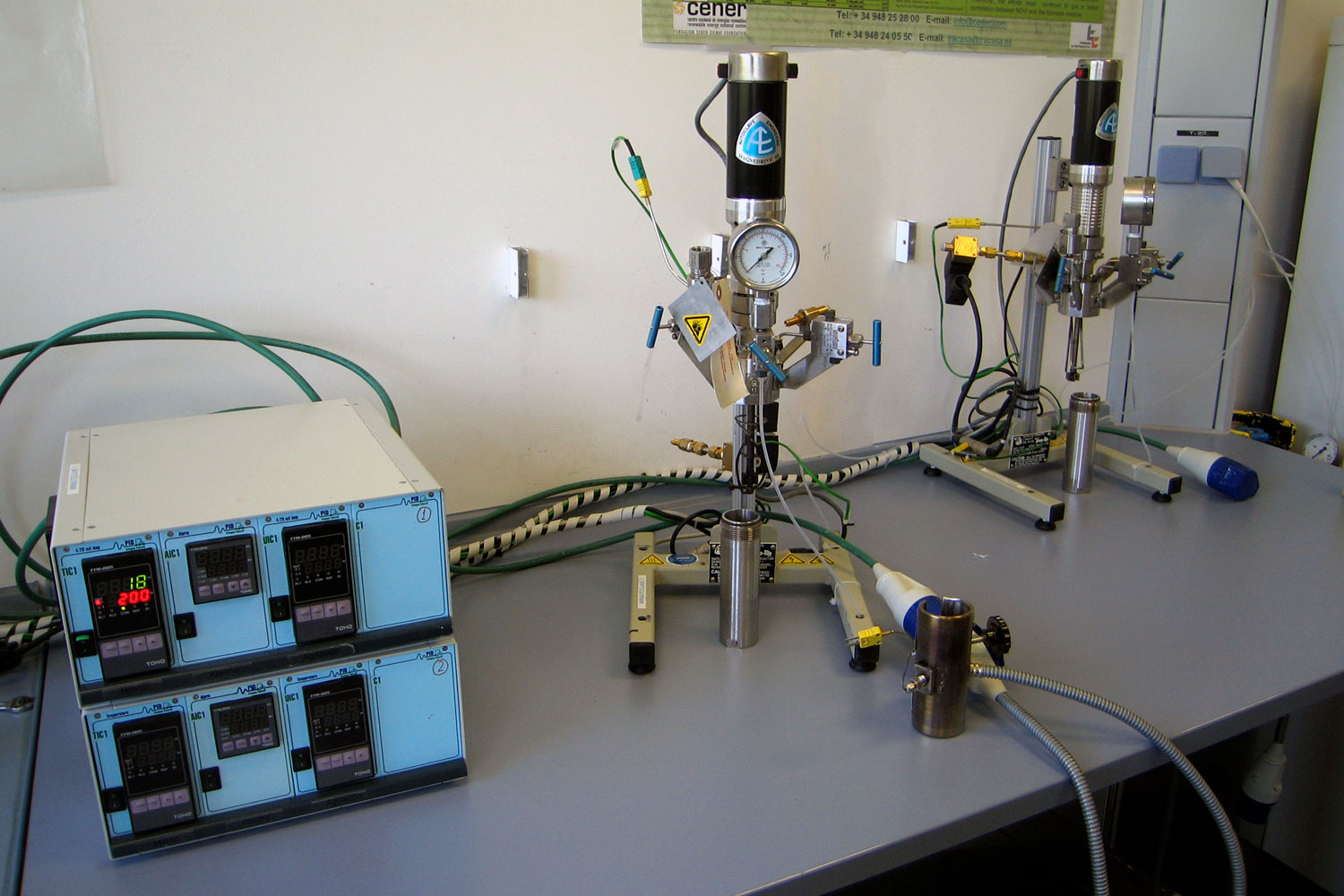

SMALL SCALE

TORREFACTION

- Batch operation mode

- 6 L volume/batch (production capacity)

- Rotary kiln directly heated reactor using ceramic band heater (200-500ºC)

- Inert gas/atmosphere selection

- Very flexible on raw material, excellent mixing & agitation, easy temperature control

- Very suitable for process and product optimization prior industrial tests

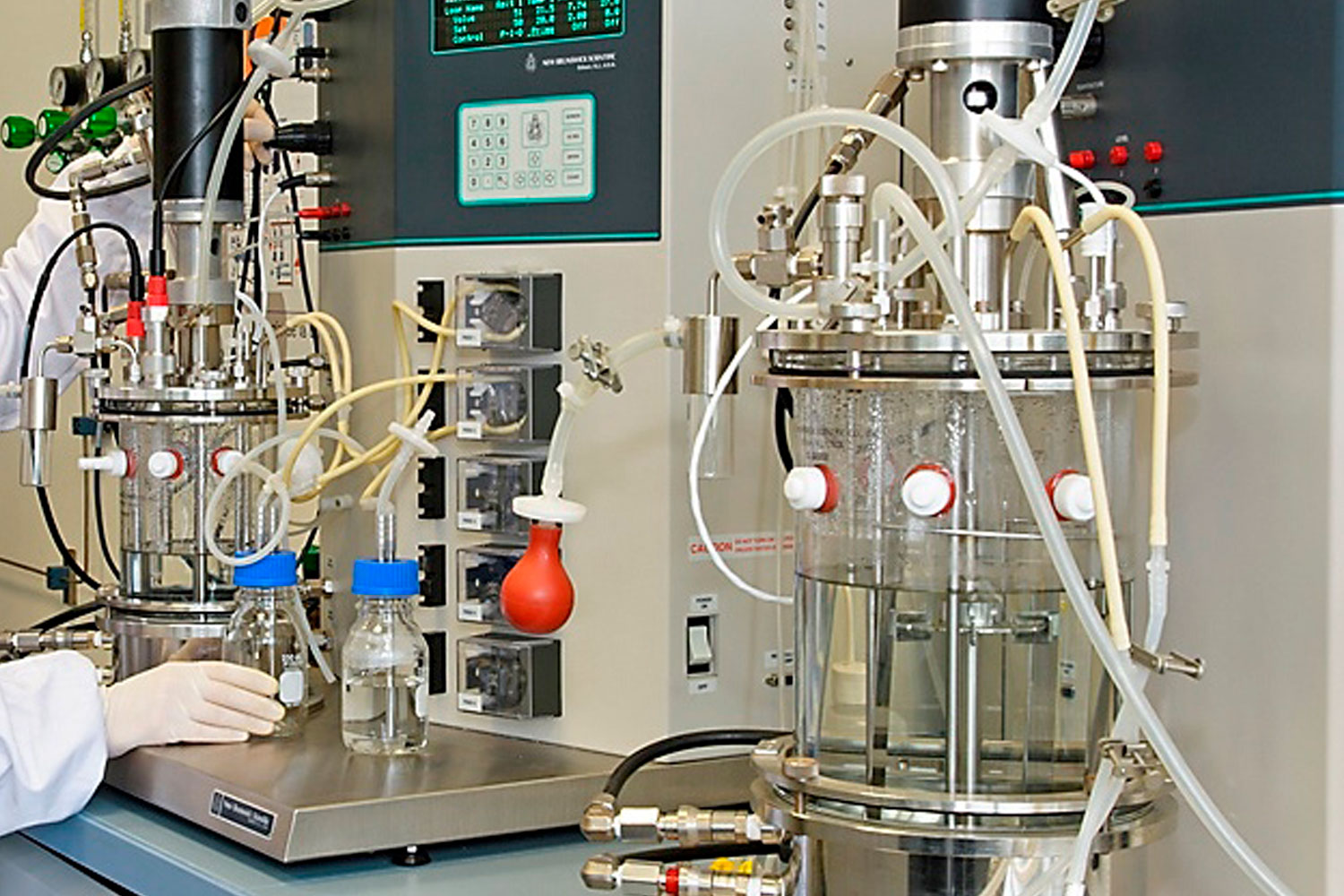

BIOCHEMICAL PROCESSES LABORATORY

Feedstock / Product characterization

- Liquid Chromatograph HPLC

- Carbohydrates/sugars

- Organic acids

- Inhibitors

- HP-SEC average molecular weight

- Gas Chromatograph GC-FID & MS

- Methanol, ethanol, butanol

- Lipids

- Elemental Analysis

- Proteins

Fractionation

/ Separation

- 4 pressurized stirred tank reactors (from 50 ml to 4L) :

- Up to 220 bar

- Up to 450ºC

- Pressure control

- Gas injection possibility

- Filtration system: MF, UF & NF

- Up to 15 bar

- Permeate flow: 0,03-6 L/h

- Interchangeable membrane module

Enzimatic Hydrolisis

& Fermentation

- Process parameters optimization in:

- From microplates: < 1ml

- Erlenmeyers or flasks: up to 1L

- Bioreactors: 2-5L

- Batch, Feed-batch, continuous

- Adjustable agitation speed, air/gas ratios, pH, nutrients

- Chambers for aerobic/ anaerobe microorganisms

- Incubator with adjustable agitation, temperature, gas inlet