- Since 2013

- 1,5t biomass/week

PRETREATMENT

SOLID / LIQUID FRACTIONATION

Biological Processes (Enzymatic Hydrolysis & fermentation)

LABORATORY:

Feedstock / Product characterization

- Liquid Chromatograph HPLC

- Carbohydrates/sugars

- Organic acids

- Inhibitors

- HP-SEC average molecular weight

- Gas Chromatograph GC-FID & MS

- Methanol, ethanol, butanol

- Lipids

- Elemental Analysis

- Proteins

Fractionation /

Separation

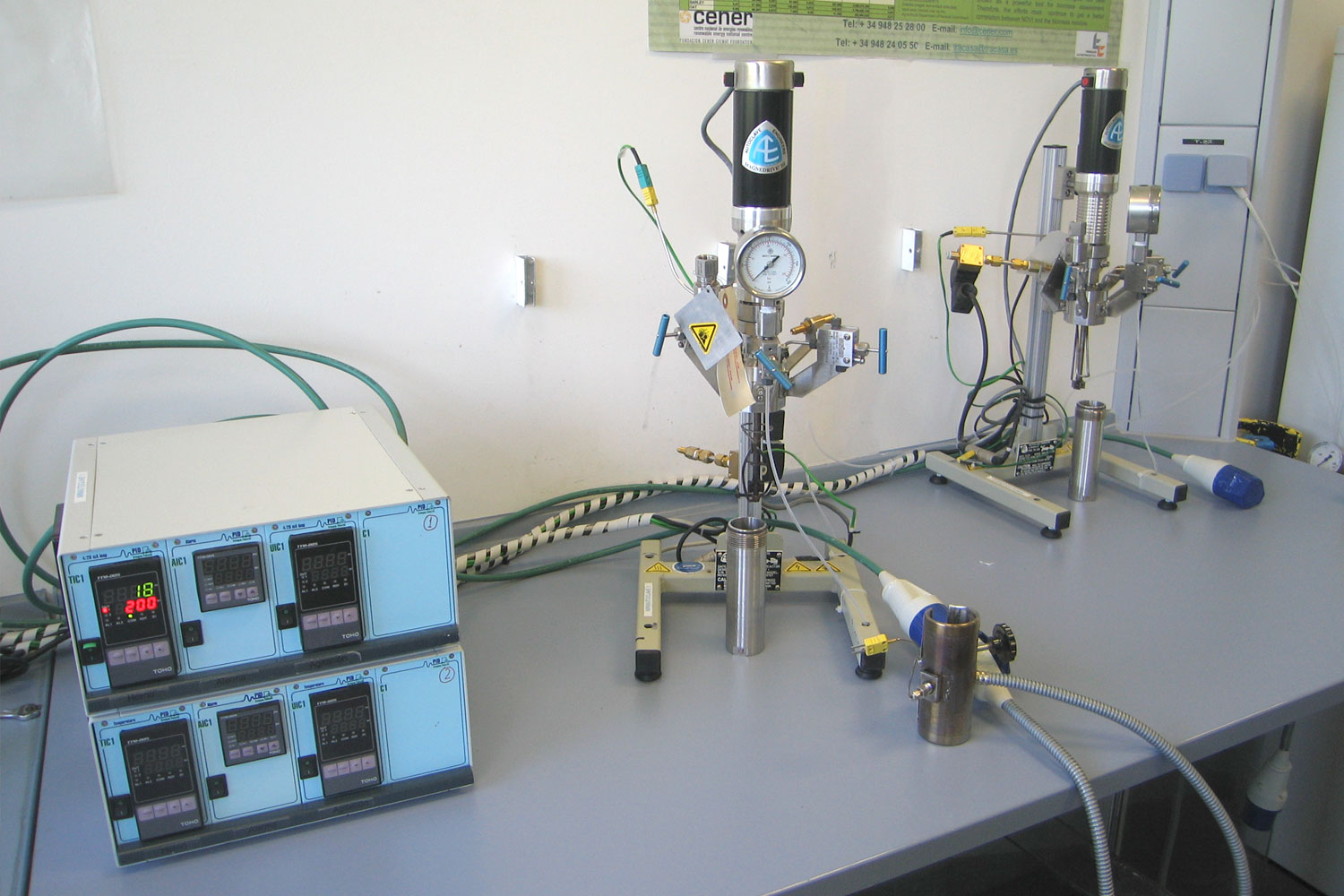

- 4 pressurized stirred tank reactors (from 50 ml to 4L) :

- Up to 220 bar

- Up to 450ºC

- Pressure control

- Gas injection possibility

- Filtration system: MF, UF & NF

- Up to 15 bar

- Permeate flow: 0,03-6 L/h

- Interchangeable membrane module

Enzimatic Hydrolisis & Fermentation

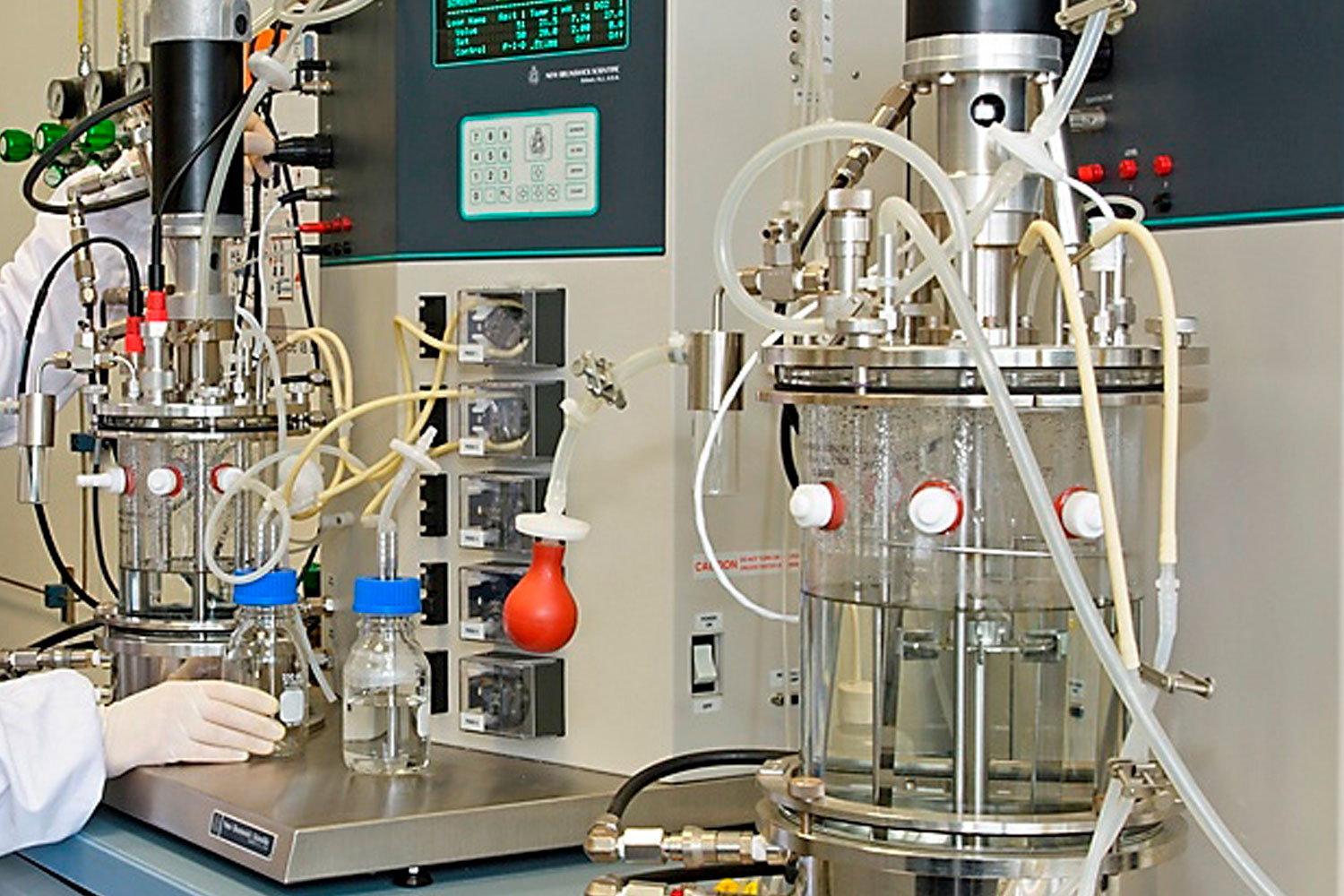

- Process parameters optimization in:

- From microplates: < 1ml

- Erlenmeyers or flasks: up to 1L

- Bioreactors: 2-5L

- Batch, Feed-batch, continuous

- Adjustable agitation speed, air/gas ratios, pH, nutrients

- Chambers for aerobic/ anaerobe microorganisms

- Incubator with adjustable agitation, temperature, gas inlet

PILOT PLANT:

Pretreatment

- Continuous horizontal reactor

- Feed flow: up to 5 kg/h

- Pressure up to 14.5 bar

- Temperature up to 200ºC

- High flexibility in feedstocks

Enzymatic Hydrolysis

- High solids enzymatic hydrolysis stirred tank reactor

- 200l capacity

- Temperature: 20-80 ºC

- Self-sterilizable

- Presurizable (min 1.5 bar/21,75 psi)

Fermentation

- Fully monitored bioreactors

- 40l and 100l capacity

- Temperature: 23-80ºC

- Adjustable agitation speed, air/gas ratios, pH, nutrients

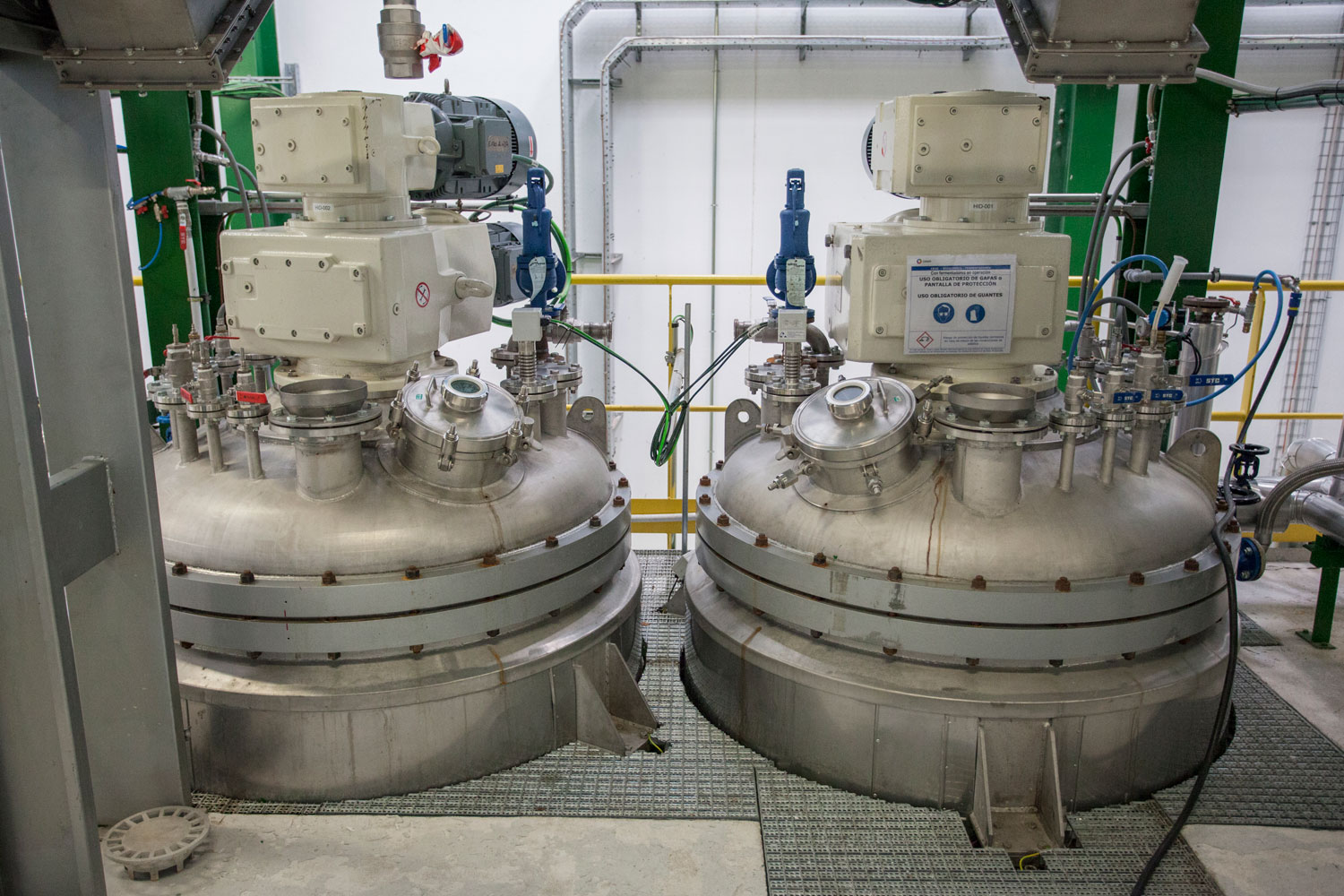

INDUSTRIAL PLANT:

Modular and flexible facility. Main equipments:

- High solid enzymatic reactors (2 x 3 m3)

- Press Filter/Centrifuge for solid- liquid separation,

- Detoxification of inhibitors

- Liquid fraction concentration

- Fermentation train consisting of several monitorized bioreactors (1, 3 and 6 m³)